High Efficient Screw Sand Washing Machine /Thickener/mineral Concentror for Mineral Dressing With ISO,CE Quality Approved

High Efficient screw sand washing machine /Thickener/mineral concentror for Mineral Dressing with ISO,CE Quality Approved

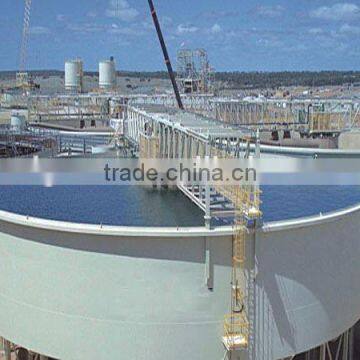

high-rate Mineral concentrator thickener for mine dress use

High Efficient Thickener for Mineral Dressing with ISO,CE Quality Approved

Mining thickener for mine dress use

Product Description

Our company develops efficient, energy-saving dewatering equipment to realize solid-liquid separation relying on the settling characteristics of the material;

The technical level has been increased greatly after recent years improvement.

No matter the overall structure of the equipments or the material selection,design,processing and purchased parts,they have been more reasonale and mature;

The drive unit of the high-rate thickener, the feed well design,manufacture(see detail in technical description) and hydraulic control system and other key parts have made great improvement,

making the technical performance of equipments can compare with the foreign imported device;

The central device of thickener(adopting hydraulic drive or planetary gearbox with electrical drive design and pinion)technology, automatic rake lifting technology, efficient tangent feed technoloy,

feeding automatic dilution system technology, efficient thickener control technology, defoaming technology and device represent the international advanced level.

Thickener — Product improvement

New mechanical structure, strengthening the flocculation of solid particleand supplying flocculent adding system

Advantages

Thickener — Advantages

Adding the flocculants to increased sedimentation particle size, thus speeding up the sedimentation velocity.

Adding the degassing tank to prevent solid particles attached to the bubbles

Setting material receiving plate and cylinder moving down, the feeding evenly and steadily falling, effectively prevent the occurrence of the splashing.

Unit processing capacity is improved by 4 ~ 9 times,and energy saving 30%.

Product Description

Thickener — Description

High efficiency thickener is not simple equipment, but with a new type of dewatering equipment mud layer filtration characteristics. Its main feature is to add a certain amount in the flocculants to be concentrated pulp, the pulp of mineral particles form flocks, accelerate the sedimentation rate, and improve the efficiency of the concentrate

Work Principle

Thickener — Work Principle

This thickener consists of round thickener and harrow scrapping machine, the solid particles suspend in thickener settling by gravity, the pulp in the upper turn into clean water, so that the separation can be realized. Slime that sediment in the bottom of the thickener is discharged by the harrow scrapping continuously, and clean overflow from the upside.

Application

Thickener — Application

Efficient thickener is widely applied in metallurgy, mines, coal, chemical industry, building materials, environmental protection and other departments, which has significance for improvement of water returning utilization rate and underflow conveying concentration.

Technical parameter of machine

Model | Tank Internal Diameter (mm) | Tank Height (mm) | Sedimen- tation Area (m2) | Rake Revolution (r.p.m) | Rake Lifting Height (mm) | Driven Motor Model | Driven Motor Power | Lifting Motor Model | Lifting Motor Power (kw) | Steel Tank Weight (kg) | Weight (kg) |

GX-3.6 | 3600 | 1700 | 10.2 | 1.1 | 200 | Y100L-6 | 1.5 | PZ0.8AB | 0.8 | 2829 | 6650 |

GX-5.18 | 5182 | 2134 | 21 | 0.8 | 300 | Y132M1-6 | 4 | PZ0.8AB | 0.8 | 5340 | 10460 |

GX-7.5 | 7500 | 2800 | 44.1 | 0.427 | 300 | Y132M2-6 | 5.5 | Y132S-8 | 2.2 | 10258 | 17320 |

GX-9 | 9000 | 2800 | 63.6 | 0.427 | 300 | Y132M2-6 | 5.5 | Y132S-8 | 2.2 | 15980 | 23680 |

GX-12 | 12000 | 3600 | 110 | 0.35 | 300 | Y132M-4 | 7.5 | Y100L1-4 | 2.2 | 25589 | 42756 |

GX-15 | 15000 | 4000 | 177 | 0.15 | 300 | YCT200-4B | 7.5 | Y112M-6 | 2.2 | 36050 | 59000 |

GX-18 | 18000 | 4400 | 254 | 0.13 | 400 | YCT200-4B | 7.5 | YCT200-4A | 5.5 | 49694 | 65992 |

GX-20 | 20000 | 4400 | 314 | 0.13 | 400 | YCT200-4B | 7.5 | YCT200-4A | 5.5 | 59365 | 81238 |

4.Technical support

5.Working condition

6.Workflow design

jedt discussion

8.Product fabrication

9.Product delivery

1.If the customers inquiry our machines, we will quote as soon as possible.

2. Our engineer will design the project according to the information our customers provide us, which is included the flow chart, the flash of project.

3. After our customer makes sure our project, please pay 30% of total amount, then we will arrange our workshop to produce the products.

4. Twenty days later, we will package and ship the goods to ours customers after recieving the whole price.

5. If our customer needs our guide, we will send our after-sales person to guide the installtion.

6. We will provide the best price of wear parts to our customers in the lifetime of the

30% of the total amount shall be paid by T/T as deposit ,balance must be paid by TT or L/C before delivery.

2.SHIPMENT:

20 working days after receiving the advance payment.

3.PACKING:

Machines will be through rusty and moist-proof before delivery; small parts are packed int- o wooden crates;larger parts are wrapped by plastic sheeting.

4.INSTALLATION:

If required, one or more engineer/engineers will be sent to guide the installation and comm issioning of machines; the buyer shall prepare the materials and tools needed,and offer ne cessary assistance.The actual expenses include accommodation, meal and traveling fee o f the engineer,and insurance also should be paid by the buyer. Every engineer should be paid 80 USD per day.

5.WARRANTY:

100% brand new when leaving the factory. The seller guarantee the quality of the machine (excluding wearing parts) for a period of one year from the date of trial run but not exceed 15 months from the date on which machine shipped out of the factory.

6.WHY CHOOSE US ?

1. We are factory,NOT Dealer All machinery from Shanghai Daiwo Machinery are made by ourselves, the lower price wit- h the same goods, good quality, after service can be assured. So please buy from factory.

2. We will do our best to satisfy every customer's needs Producing high-quality and reliable machines is our first priority, because we know that our success depends entirely on the sa tisfaction of our customers. We never give-up quality to save cost.we will leave 5% retentio n money for 3 months to show our sincerity. You can pay it after the machine go into norm al operation.

3. Training & service Training is FREE to every customer. Whenever you need us, for installation, maintenance, or proper use of our company machines, we will be right there for you. In addition, we provi de one-year warranteeto make sure your machine runs consistently. We always keep certa in inventory level of spare parts, which means the replacements can be shipped to you righ t away.

4. If you are new for this business, I will help you Many thanks for your trust; we can provid e you with the pre-services of design scheme for complete production lines, spot inspectio n and operator training according to your demands and the conditions of applied spot, we can help you choose the right equipments, drilling rig, Loader, trucks, excavators and so on. 5. We will recommend a suitable type for you and send you a best quotation.

Name:Anne Chang

Skype:anna1983cyj

Tel:+0086-18678029069

Fax:+0086-0536-3163838

Mobile:+8618678029069

Wechat:18678029069

Weifang Guote Mining Equipment Co.,Ltd

Address:Dongjing Road East,Economic Development Zone,Qingzhou City,Shandong Province,China

Send Inquiry to This Supplier

You May Also Like

-

Mineral Grinding Machine /Ball Mill (Capacity 1 to 80 Ton per Hour) for SaleUS$ 1,000 - 10,000MOQ: 1 Set

-

Grinding Equipment / Ball Mill for Gypsum, Glass, Cement Clinker, Ceramic, Etc.US$ 1,000 - 10,000MOQ: 1 Set

-

Capacity 1 to 80 Ton per Hour Ball Mill for SaleUS$ 1,000 - 10,000MOQ: 1 Set

-

Wet Ball Mill And Dry Ball Mill for Silica Sand Production LineUS$ 2,000 - 60,000MOQ: 1 Set

-

Micron Grinding Ball Mill Assembled With Air Classifier is Suitable for Quartz Powder Production LineUS$ 2,000 - 60,000MOQ: 1 Set

-

China Ball Mill for Silica Flour Production LineUS$ 1,000 - 10,000MOQ: 1 Set

-

Ball Mill is Suitable for Silica Sand Production LineUS$ 1,000 - 10,000MOQ: 1 Set

-

Mineral Grinding Machine /ball Mill Certificated ISO9001:2008 for Quartz,felspa,calcite,marble,etc.US$ 1,000 - 10,000MOQ: 1 Set

-

Grinding Equipment 18KW - 800KW Ball Mill Machine for Silica Sand Production LineUS$ 1,000 - 10,000MOQ: 1 Set

-

Latest Technology Mineral Grinding Machine for SaleUS$ 1,000 - 10,000MOQ: 1 Set